In the oil and gas industry, pipeline pigging is essential for maintaining flow efficiency, preventing blockages, and ensuring system integrity. But pigging isn’t just about performance—it’s also about safety. Improper handling, poor planning, or lack of training can turn a routine pigging operation into a hazardous event.

This article outlines the most critical pipeline pigging safety practices, so operators can carry out cleanings, inspections, and maintenance without unnecessary risks. With expert tools and guidance from Sun Pipeline Solutions, you can count on safe, effective, and compliant pigging operations from start to finish.

Why Pipeline Pigging Safety Matters

While pigging may appear straightforward, it involves high pressures, flammable materials, heavy equipment, and confined spaces—conditions where the smallest oversight can lead to serious incidents.

The most common pigging-related risks include:

- Uncontrolled pressure releases

- Pig launch or retrieval accidents

- Explosions or fire hazards

- Chemical exposure

- Equipment failure

By following proven best practices and using quality pigging products from Sun Pipeline Solutions, operators can reduce risk, protect personnel, and ensure compliance with safety standards.

1. Plan Every Pigging Operation Thoroughly

Every pigging run should begin with a detailed plan. This includes:

- Reviewing pipeline schematics

- Confirming product type and flow conditions

- Selecting the correct pig for the task

- Identifying potential obstructions or operational challenges

- Communicating responsibilities and procedures with the team

Proper planning reduces the likelihood of unexpected pressure surges, stuck pigs, or release of hazardous materials.

2. Use the Right Pig for the Job

Not all pigs are created equal. Using the wrong type of pig can cause internal damage, get stuck in the line, or compromise cleaning or inspection outcomes.

Choose from:

- Foam pigs for drying, light cleaning, and displacement

- Steel or urethane pigs for aggressive cleaning or high-pressure systems

- Smart pigs for in-line inspection and corrosion detection

Sun Pipeline Solutions offers a wide variety of high-performance pipeline pigs designed for safety, precision, and durability in every type of operation.

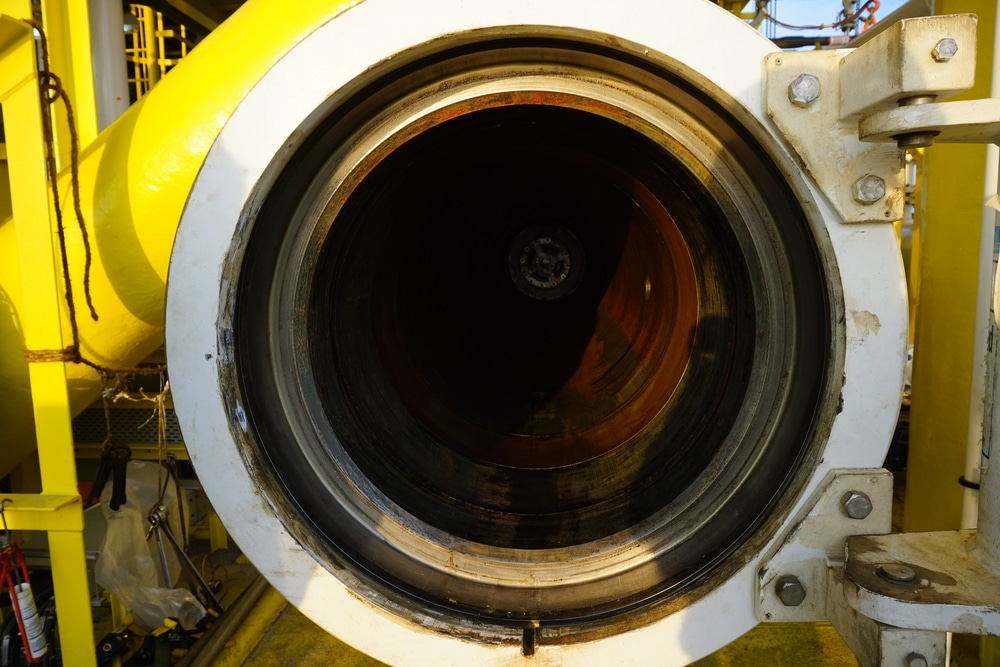

3. Inspect Pigging Equipment Before and After Use

Always perform pre- and post-operation checks:

- Ensure launcher and receiver are sealed and depressurized

- Inspect valves and vent systems for wear or blockage

- Check for damage or wear on pigs

- Test pressure indicators and safety relief devices

Preventive maintenance can mean the difference between a smooth operation and a dangerous failure.

4. Follow Strict Pressure Control Procedures

Pigging should never be performed under uncertain pressure conditions. Key pressure safety steps include:

- Confirming complete depressurization before opening closures

- Gradually equalizing pressure when launching or receiving pigs

- Monitoring system pressure in real time

- Using pressure-rated components tested for your pipeline’s specific operating range

Even minor missteps in pressure control can cause projectile risks, pipe rupture, or chemical exposure.

5. Ensure Personnel Safety at All Times

Field teams must be properly trained and equipped. Best practices include:

- Wearing full PPE (gloves, helmets, eye protection, FR clothing)

- Following lockout/tagout procedures

- Maintaining safe distance during launch/retrieval

- Using tools designed for ergonomic, safe pig handling

- Communicating clearly during all phases of pigging

Sun Pipeline Solutions supports operational teams with expert training and pigging tools engineered for maximum safety and performance.

6. Keep Accurate Records and Documentation

Detailed documentation helps in incident prevention, troubleshooting, and regulatory compliance. Maintain logs for:

- Type and condition of pigs used

- Pressure readings and flow rates

- Maintenance records

- Operational steps followed

- Any incidents or near misses

Reliable data helps improve future pigging runs and audit readiness.

Final Thoughts

Safe pipeline pigging isn’t optional—it’s essential for operational efficiency, environmental protection, and worker safety. By following best practices and partnering with an experienced provider like Sun Pipeline Solutions, companies can carry out pigging operations with total confidence.

From planning and pig selection to pressure control and post-run inspection, every step matters. Choose the right pigs, train your teams, and commit to the highest safety standards in the industry.

For trusted pipeline pigging products and support, turn to Sun Pipeline Solutions—where safety and performance go hand in hand.